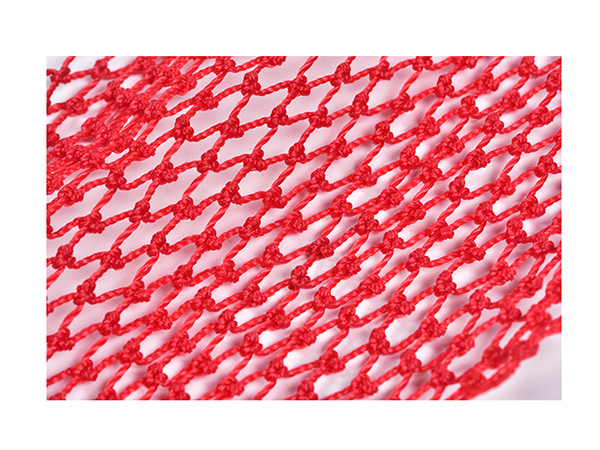

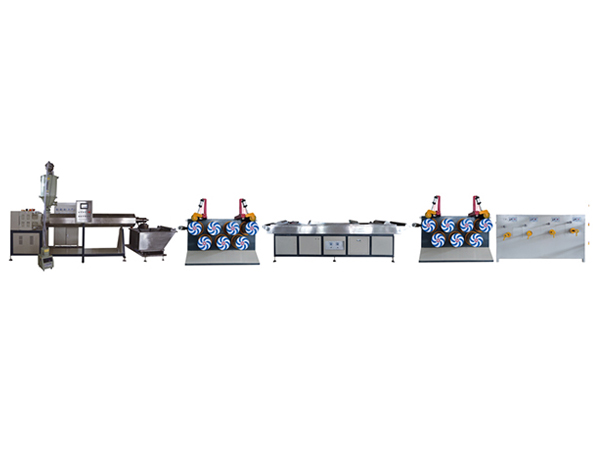

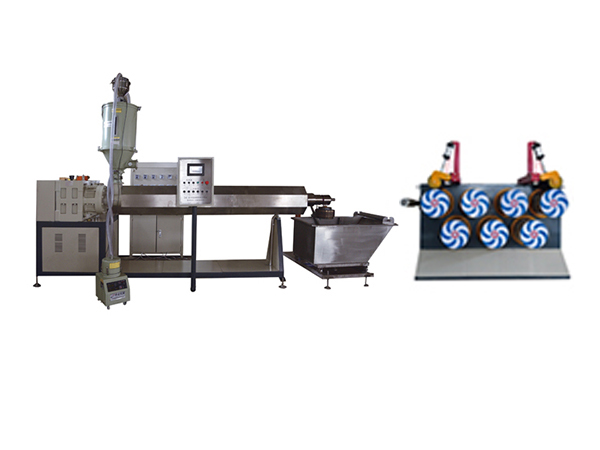

The rope making machine has compact structure, easy operation, good product quality and low machine repair rate. There is no need for processes such as making strands first and then forming ropes, and the twist of strands and ropes can be adjusted at will. There is no waste silk and waste. The ropes are beautiful and durable. Now let's introduce the maintenance method of rope making machine.

1. Check the smooth parts of the rope making machine, and carry out appropriate smooth maintenance for all driving sprockets, gears, chains, bearings and other parts of the rope making machine, once a week; Appropriate smooth maintenance shall be carried out for the relevant parts of the wire setter once a week.

2. It is necessary to confirm that there is no obstruction within the action range of the machine and check it at any time. Tighten the screws at the driving and connecting parts of the rope making machine to avoid loosening and affecting the work of the rope making machine. Check it once a week. Before operating the rope making machine, please work at low speed for about 5 minutes before increasing the speed.

3. Check whether the electrical power distribution device of rope making machine, such as frequency converter, meter counter, inductor, button, relay, line, etc. are normal.

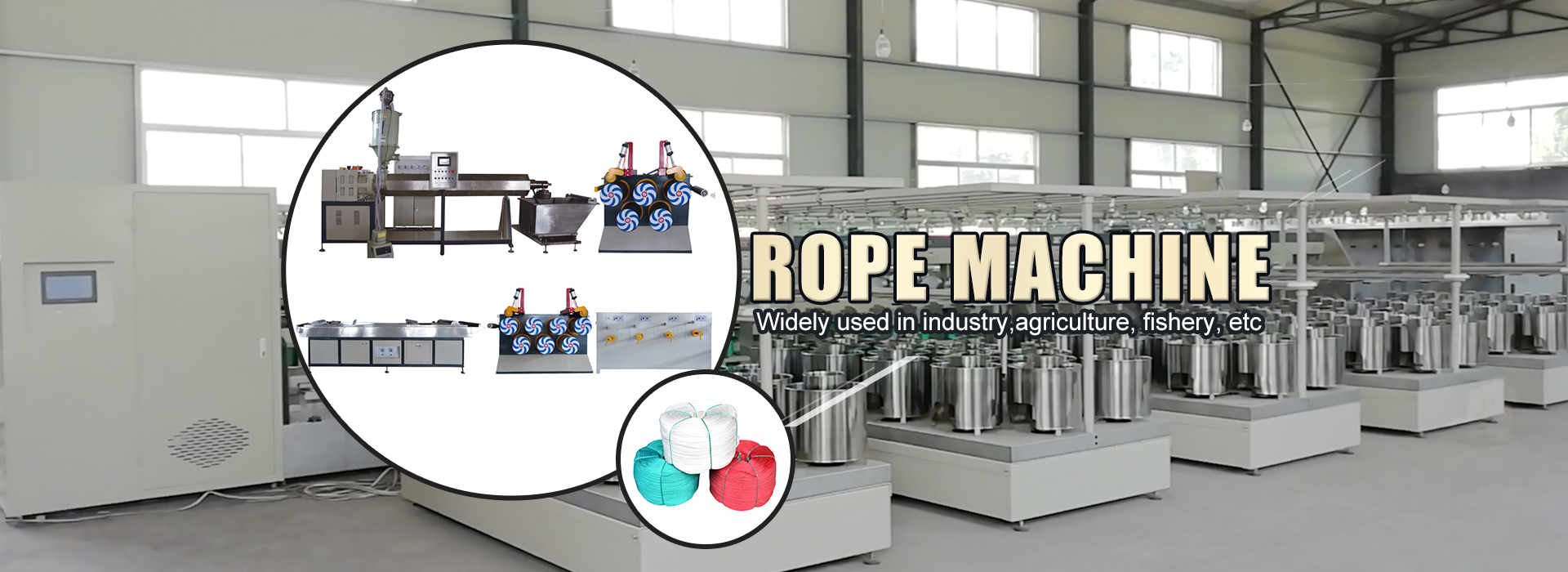

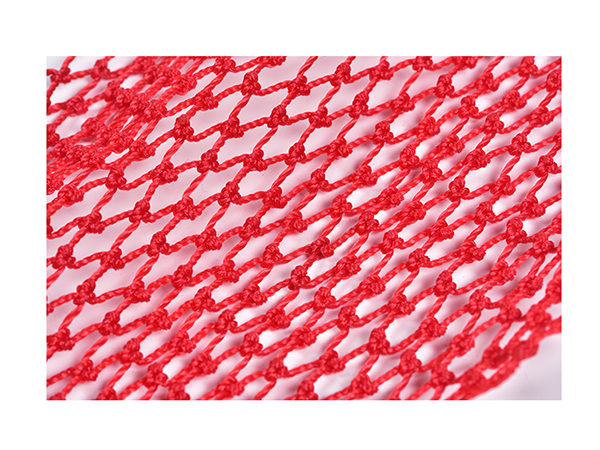

The built-in active rope guide of the rope making machine can make the reel rope orderly and actively arrange the rope into a reel. The meter can increase or decrease the rope making length and weight at will according to the production requirements, and can automatically shut down when reaching the value specified by the user. The rope making machine is suitable for the rope making industry with sisal jute fiber, plastic and nylon long thread as materials.